Blogs & RFQ

Gas Cylinder Safety: Types, Storage & Color Codes | LITEN Industrial Guide

I. Concept of Gas Cylinders:

A gas cylinder refers to a type of movable pressure vessel with a bottle-shaped main structure, generally filled with gases (which can be compressed gases, liquefied gases, dissolved and adsorbed gases, etc.). Gas cylinders are widely used and are almost indispensable in both production and daily life fields. As pressure-bearing equipment, gas cylinders have explosion risks, and the media they contain usually have properties such as flammability, explosiveness, toxicity, and strong corrosiveness. Due to their characteristics of being movable, repeatedly filled, having non-fixed operators, and changing usage environments, their service environment is more complex and harsh than that of other pressure vessels. Once a gas cylinder explodes or leaks, it often leads to fires or poisoning, and even catastrophic accidents, resulting in serious property losses, casualties, and environmental pollution.

II. Classification of Gas Cylinders:

(1) Classification by the nature of the filling medium: They can be divided into permanent gas cylinders, liquefied gas cylinders, and dissolved gas cylinders.

(2) Classification by manufacturing method: They can be divided into seamless steel cylinders, welded steel cylinders, and glass fiber-wound cylinders.

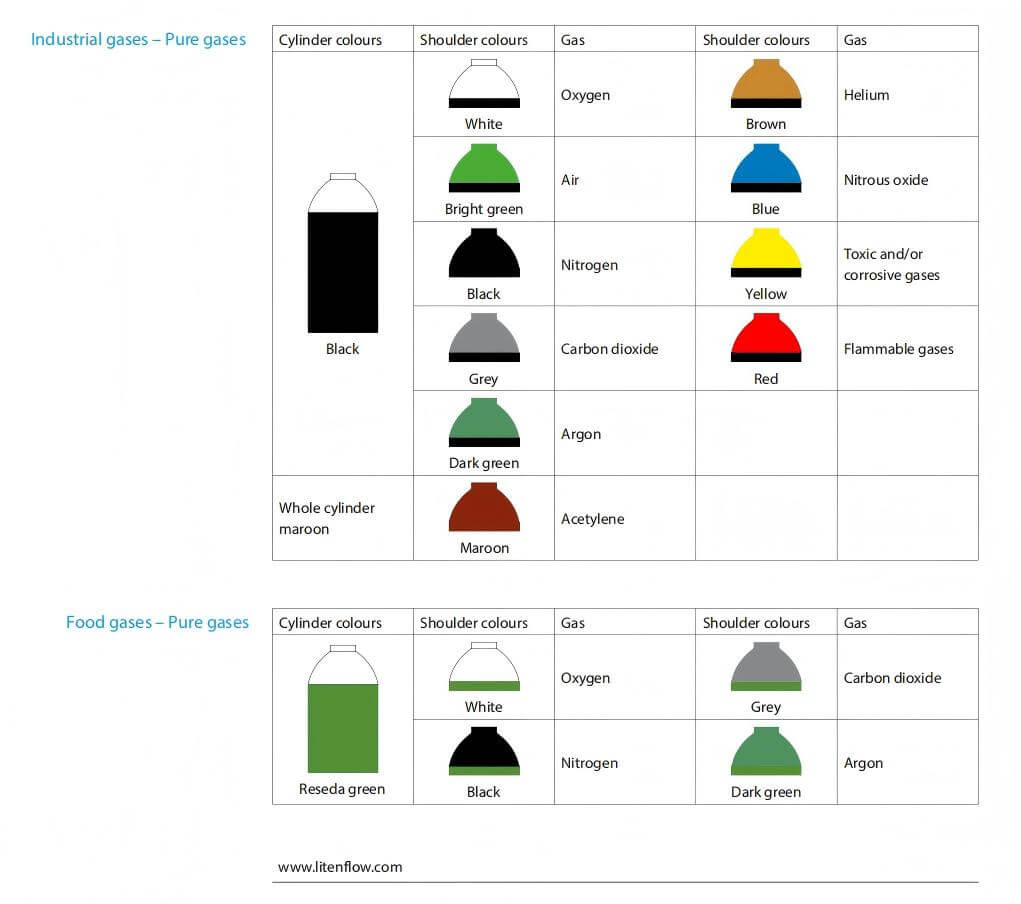

(3) Classification by nominal working pressure: Gas cylinders are divided into high-pressure cylinders and low-pressure cylinders according to their nominal working pressure. Among them, oxygen, acetylene, liquefied gas, and carbon dioxide cylinders are more common at construction sites, with their respective colors as follows: light blue with "oxygen" written on it, white with "acetylene" written on it, silver gray with "liquefied petroleum gas" written on it, and aluminum white with "liquefied carbon dioxide" written on it.

III. Nominal Volume and Pressure of Gas Cylinders:

1. The nominal volume of a gas cylinder refers to the graded series of cylinder volumes specified in cylinder regulations and standards. Like the nominal working pressure, the nominal volume is a nominal value rather than an accurate actual value. For safety, the actual volume of a gas cylinder must be greater than the nominal volume, with a tolerance of +5%. It can be seen that although the nominal volume is a nominal value for designation, it is strictly restricted and cannot be casually named. For example, a seamless cylinder with a nominal volume of 40L should have an actual volume between 40L and 42L. For the convenience of management, China classifies the nominal volume of gas cylinders into three categories: small, medium, and large. Those with a volume of 12L (including 12L) or less are small-volume; those with a volume greater than 12L up to 100L (including 100L) are medium-volume; and those with a volume greater than 100L are large-volume.

2. The allowable pressure of a gas cylinder is the maximum pressure that the cylinder is allowed to bear, which should not be less than the medium pressure inside the cylinder when the medium is at 60°C. The allowable pressure of a steel gas cylinder must not exceed 0.8 times the hydrostatic test pressure. The hydrostatic test pressure of a steel cylinder is 1.5 times the nominal working pressure.

IV. General Storage Principles and Regular Inspection & Scrap of Gas Cylinders:

1. Upright Storage: Cylinders should be placed upright in dedicated brackets or cages, and fixed with anti-vibration gaskets and cylinder caps.

2. The storage quantity of flammable gas cylinders such as acetylene cylinders must not exceed 30 cubic meters (approximately 5 standard 40-liter cylinders). If the quantity exceeds this, non-combustible materials must be used for isolation or a dedicated storage room must be built. If the storage quantity exceeds 240 cubic meters (approximately 40 cylinders), a warehouse with a fire resistance rating of not less than Class II must be built, and it should be kept at least 10 meters away from buildings or separated by firewalls.

3. Flammable gases (such as acetylene) and oxidizing gases (such as oxygen) must be stored separately; mixing storage is strictly prohibited. Empty cylinders, full cylinders, cylinders in use, and standby cylinders should be placed separately, with anti-tipping measures taken.

4. Prohibition of Mixed Storage: It is strictly forbidden to come into contact with flammable substances, live objects, or heat sources; using the cylinder valve as a lifting point or handle is prohibited.

5. Regular Scrap: Gas cylinders require regular inspection (generally, gas cylinders are inspected every three years), and it is necessary to confirm that accessories (such as pressure reducing valves and pressure gauges) are in good condition before use. See the table below:

No.

Cylinder Type

Inspection Interval

1

Seamless Steel Gas Cylinders and Seamless Aluminum Alloy Gas Cylinders

(1) For cylinders filled with nitrogen, helium, argon, hexafluoride, inert gases, and gases with purity ≥99.999%: inspect every 5 years;

(2) For cylinders filled with gases that may cause corrosion to the cylinder material, underwater cylinders, and cylinders frequently exposed to seawater: inspect every 2 years;

(3) For cylinders filled with other gases: inspect every 3 years.

2

Steel Welding Gas Cylinders

(1) For cylinders filled with general gases: inspect every 3 years;

(2) For cylinders filled with corrosive gases: inspect every 2 years.

3

Dissolved Acetylene Cylinders

Inspect every 3 years.

4

Liquefied Petroleum Gas Cylinders

According to GB8334 standard, generally inspect every 4 years.

5

Vehicle Liquefied Petroleum Gas Cylinders

Inspect every 5 years.

6

Welding Insulation Gas Cylinders

Inspect and maintain every 5 years.

7

Vehicle Compressed Natural Gas Welding Insulation Cylinders

Inspect and maintain every 3 years.

8

Respirator Composite Cylinders

Inspect every 3 years.

9

Vehicle Winding Gas Cylinders

Inspect every 3 years (or shorten the period according to local standards).

10

Vehicle Compressed Natural Gas Cylinders

(1) Inspect every 3 years for the first time, then every 2 years thereafter;

(2) For those used in rental vehicles, inspect every 2 years for the first time, then every year thereafter.

No.

Cylinder Type

Designed Service Life

1

Seamless Steel Gas Cylinder

30 years

2

Steel Welded Gas Cylinder

30 years

3

Seamless Aluminum Alloy Gas Cylinder

20 years

4

Long Tube Trailer, Tube Bundle Container with Large Volume Seamless Steel Gas Cylinder

20 years

5

Dissolved Acetylene Cylinder and Steel Welded Cylinder for Natural Gas

20 years

6

Vehicle Compressed Natural Gas Cylinder

15 years

7

Vehicle Liquefied Petroleum Gas Cylinder and Vehicle Dimethyl Ether Cylinder

15 years

8

Steel Liner Hoop-Wound Composite Cylinder

15 years

9

All-Wound Composite Cylinder with Aluminum Alloy Liner

15 years

10

Hoop-Wound Composite Cylinder with Aluminum Alloy Liner

15 years (or 8 years) (Note 1)

11

Civil Liquefied Petroleum Gas Cylinder, Chlorine Cylinder

15 years

12

Cylinders Used in Strongly Corrosive or Isolated Environments, such as for Storing Highly Toxic Gases

12 years

V. Transportation and Handling of Gas Cylinders:

Requirements for transporting gas cylinders

1.1 Vehicles used to transport gas cylinders must be marked with a "dangerous goods" safety sign.

1.2 Cylinders must be equipped with caps and anti-vibration rings. If a pressure reducer is installed, it should be removed. The cylinder cap must be tightly screwed to prevent accidents caused by broken cylinder valves due to falling.

1.3 Cylinders should be loaded upright on the vehicle and properly secured to prevent tilting, toppling, or falling. The height of the carriage must be more than two-thirds of the cylinder height.

1.4 When a cylinder transport vehicle is parked, the driver and escort must not leave at the same time. Such vehicles must not park in busy urban areas or near crowded places. Acetylene cylinders should not be transported over long distances.

1.5 Vehicles transporting flammable or toxic gas cylinders must be equipped with fire-fighting equipment or gas masks.

1.6 During transportation in summer, sunshade facilities should be provided, and proper covering should be used to avoid exposure to direct sunlight.

1.7 Cylinders containing media that can ignite, explode, or produce toxic substances when in contact with each other must not be transported in the same vehicle. Flammable materials, greases, and oily items must not be transported together with oxygen cylinders or cylinders containing strong oxidizers.

1.8 Except for the driver and escort, no unrelated persons are allowed to ride in the vehicle. Drivers and passengers are strictly prohibited from smoking or carrying fire sources.

Requirements for handling gas cylinders

2.1 When handling cylinders, screw the cylinder cap tightly and move them in an upright position. Handle with care, avoiding rough handling. Lifting cylinders by the cap is prohibited.

2.2 For short-distance movement (within 5 meters), hold the shoulder of the cylinder and rotate the bottom, and gloves must be worn. For longer distances, use a trolley to transport the cylinders; in special cases, appropriate safe methods can be adopted.

2.3 It is forbidden to carry cylinders over 1.5 meters high by hand into trolleys or special hanging baskets. Instead, use the method of holding the shoulder and rotating the bottom.

2.4 When unloading, place a soft pad or rubber mat at the landing point of the cylinders, unload them one by one, and sliding or rolling is strictly prohibited. When loading or unloading oxygen cylinders, work clothes, gloves, loading and unloading tools, and machinery must not be contaminated with grease.

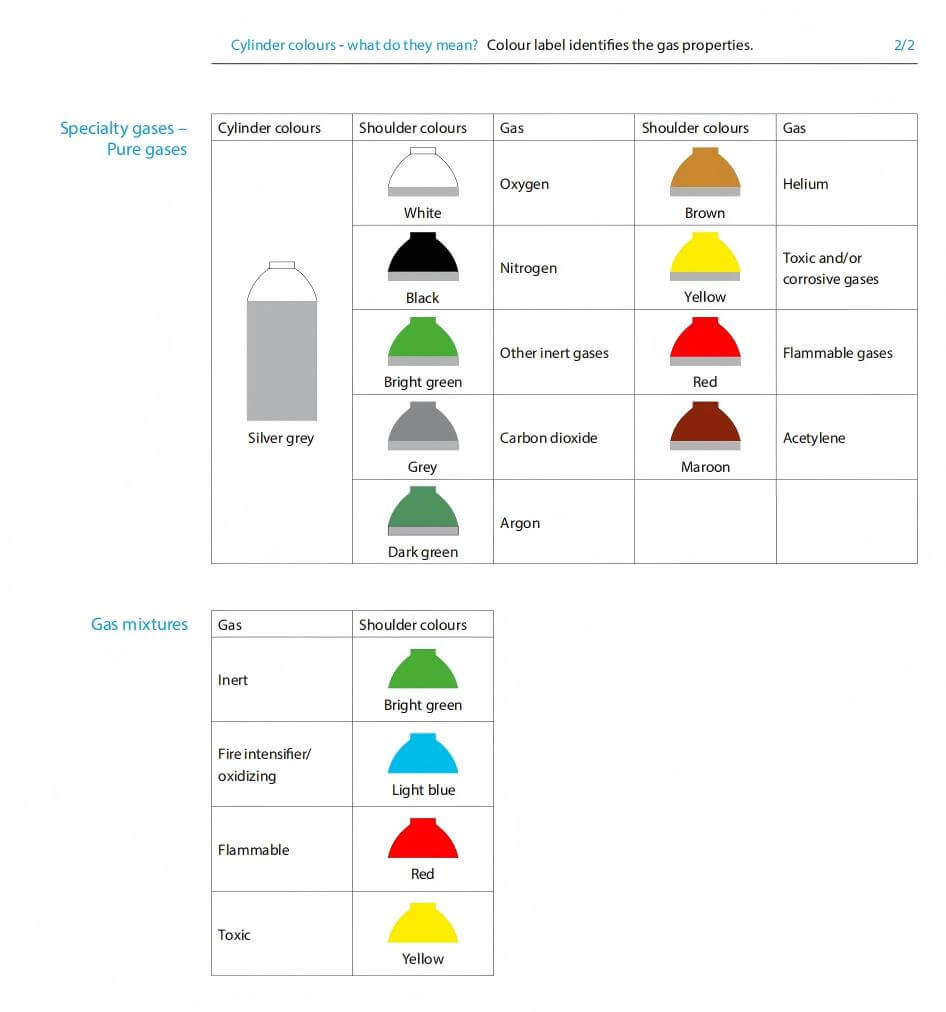

VI. Color Markings of Gas Cylinders: